Product description

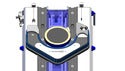

The Dual Line Balancer is designed for dynamic, pressureless accumulation by extending the production line temporary in two parallel lanes.

It ensures a smooth and gentle product flow, ideal for high-speed lines where balancing between upstream and downstream equipment is critical.

keeping fillers and packers supplied during micro-stops. It absorbs short disturbances and meters a consistent outfeed, so upstream and downstream machines run at optimum efficiency.

- Synchronized FIFO on twin lanes, zero back-pressure

- Compact footprint with flexible in/outfeed geometry

- Gentle handling for fragile PET, glass, cartons

- Low maintenance, modular build for easy service

- Options & combinations: sensors, covers, drip trays, single-liner, dividers/mergers

Specifications

- Function: buffering & line balancing (FIFO, twin-lane)

- Applications: bottles, cups, trays, cartons; dairy, beverages, convenience foods

- Max. speed / capacity: up to line speed; typical 20–90 m/min / up to ~30,000 bph

- Dimensions: modular lane length & width; compact footprint for integration

- Frame / Materials: stainless steel (hygienic design), food-grade plastics

- Chain / Belt type: low-friction slat chain / modular belt

- Drive / Controls: VFD speed control; stand-alone or line-integrated

- Sustainability / Hygiene: easy to clean, low wear, reduced waste